Context

For a while I have been dwelling about a simple AUV for assistance in several projects I am involved in. I have used a couple of commercial units and they have been successful but have had some (often significant) drawbacks which we (as a community) may in part be able to be overcome.

There have been a few somewhat more cost-effective units out there Seaber Yuco, (starting at about US$65k) MIT Sea Scout (commercialised here?), NemoSens, EcoMapper Nano (in collaboration with Seaber), Oceanscan LAUV (rental approx. US$2.5k/day) before you get into the bigger (and more commercial) units (the actual number of these smaller units in the field units would be interesting maybe aside from Seaber the others would be a handful or two each?)

Additionally, several people on the forum seem to be developing or progressing in somewhat similar directions and sharing of concepts may be advantageous to all.

Given that, my base core requirements are:

- Must (Non-Negotiable for my use case) be able to be travel with it on international flights

- Battery - Must be removable (not on several of the commercial units)

- Battery - Must be able to be broken down into sub 100Whr elements (see here)

- Weight - Unit without battery but plus hard travel case (say 10kg) must be less than 30kg (flight luggage limits)

- Must able to scan medium sized areas (say 5km by 5km) can be across multiple missions

- Ideally not be a 1 trick pony – able to be configured to give more than a single use case

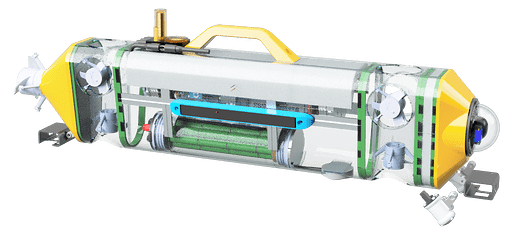

Suggested Base Modular Blue Robotics Based AUV

The aim (in part) is to keep it using as many stock standard parts and systems as possible (to accelerate its use). But also, able to have modules swapped out as elements of the system develop. I see it all as a way to get something moving so some of the larger issues can be worked out sort of down the path similar to the initial Bluerobotics ROV.

As it currently stands, I envisage the following style modules

- Rear Thruster Module (about 1.6kg)

- Lateral Thruster Module. (about 1.1kg)

- Main Body Module (about 8.4kg with battery 6.9kg without)

- Support Frame

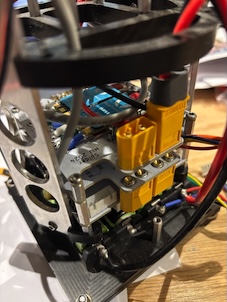

- Main 4” Electrics Enclosure with Integral Payload Electrics Tray

- 3” Battery Enclosure

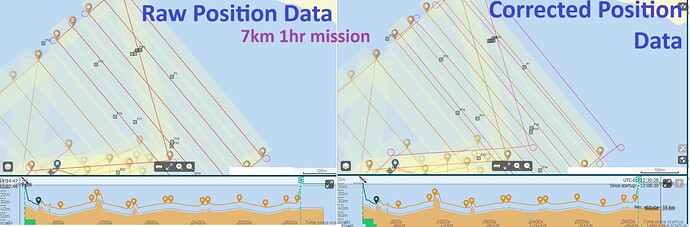

- DVL add in module (nonbrand specific)

- Nose Module (about 0.7kg with camera)

- Camera / Lights Module

- Handle / Communications Module (not detailed as yet)

- Buoyancy Module

- Nominal 60mm (0.9kg buoyant)

- Nominal 100mm (1.6kg buoyant)

- Ancillary Payload Module

- Additional 4” Electrics Enclosure

- Additional 3” Battery Enclosure

3D model Fusion Link https://a360.co/4lOpoXn

Medium unit with Side Scan and Camera module Unit Approximately 13.5kg (slightly buoyant as configured in the image)

Base Concept (11.6kg) with Pelican Air 1745 through to Most Module options (20.2kg) Side Scan Sonar, Additional thrusters, Ancillary Payload and Additional battery in a Pelican Air 1755

So, as I see it for a Base Unit

- Blue Robotics Parts approximately Around US$5.5K (depth limit to 300-500 meters)

- Batteries Around US$0.5K

- Custom Pieces Around US$2K (I have access to 4 axis CNC, CNC Router and 3D printer)

- DVL Brand and Feature dependent US$2K-10K (depth limit to say 300 meters)

Adding a Sidescan Module (fits within the proposed standard Main 4” Electrics Enclosure with Integral Payload Electrics Tray [takes up approx. ½ of Integral Payload Electrics Tray])

- Sidescan Brand and Feature dependent US$2K-10K (depth limit to say 300 meters)

So, around the US$10K minimum (even less if no DVL and dragging a surface buoy for positional info) but more realistically a well-functioning unit around US$ 16.5K and with a few more tweaks US$26K broken up as. (to give indication as to where the most cost-effective cuts/tweaks can be made – [makes opensource underwater acoustics look good])

| Source | Minimum | Well-functioning | Higher end |

|---|---|---|---|

| Blue Robotics Parts | 25% | 24% | 21% |

| DVL | 20% | 34% | 30% |

| SSS | 33% | 31% | 39% |

| Customs | 16% | 11% | 10% |

I have started to develop several (most of the modules above) to say a 50% design level (physicality sorted out but tweaking of where screw connections and alike still to be done). I believe strongly in the wisdom of the crowd and that this is not my design but open to all. Hence, I am looking for feedback, it’s easier and better to fix things on paper than when hardware has been purchased or fabricated.

I am not wedded to any specific concept and am happy to discuss any of the elements, there are some elements I have not started on (Handle / Communications module as I am in 2 thoughts (a fully integrated version [GPS and Lora in the main electronics and just aerials in the handle] or one which is a complete standalone unit [complete with independent battery and runs independent from the AUV/ROV]) Happy for peoples thoughts and concepts (I note @gunthix and his unit)

I see a large opportunity where a significant number of different payloads could be implemented to give really great versatility to this base backbone.

I will post more details of individual elements, I know I cannot do this alone (my software level is mmmmm average to poor on a good day basic)

Scott